Ityhubhu yokugquma irabha yeKingflex foam

Inkcazo

Iimveliso zokugquma irabha yeKingflex foam zizinto ezahlukeneyo ezisetyenziswayo. Irabha ye-close cell ifumaneka kwiintlobo ngeentlobo zeemveliso. Ishishini leemoto: ii-gaskets ezikhanyayo, inkqubo yomoya opholileyo, iibhodi zedeshibhodi, iinjini. Ishishini lezakhiwo: ii-gaskets, ii-wedges. Ishishini leRailway: ii-pads zesitimela. I-Marine: ii-gaskets, ukhuseleko lomlilo, iseti yoxinzelelo oluphantsi, ukukhutshwa okuphantsi. I-elektroniki: ii-gaskets, umoya opholileyo.

Iphepha leDatha yoBugcisa

| Idatha yoBugcisa yeKingflex | |||

| Ipropati | Iyunithi | Ixabiso | Indlela yoVavanyo |

| Uluhlu lobushushu | °C | (-50 - 110) | GB/T 17794-1999 |

| Uluhlu loxinano | Iikhilogremu/m3 | 45-65Kg/m3 | I-ASTM D1667 |

| Ukuvuleka komphunga wamanzi | kg/(mspa) | ≤0.91×10 ﹣¹³ | DIN 52 615 BS 4370 Icandelo 2 1973 |

| μ | - | ≥10000 | |

| Ukuqhuba kweThermal | W/(mk) | ≤0.030 (-20°C) | I-ASTM C 518 |

| ≤0.032 (0°C) | |||

| ≤0.036 (40°C) | |||

| Uvavanyo loMlilo | - | Iklasi 0 kunye neKlasi 1 | BS 476 Icandelo 6 inxalenye 7 |

| Isalathiso Sokusasazeka Kwelangatye kunye Nophuhliso Lomsi |

| 25/50 | I-ASTM E 84 |

| Isalathisi seoksijini |

| ≥36 | I-GB/T 2406, ISO4589 |

| Ukufunxwa kwamanzi,%ngoMthamo | % | 20% | I-ASTM C 209 |

| Uzinzo lobukhulu |

| ≤5 | I-ASTM C534 |

| Ukumelana neefungus | - | Kulungile | I-ASTM 21 |

| Ukumelana ne-ozone | Kulungile | GB/T 7762-1987 | |

| Ukuchasana ne-UV kunye nemozulu | Kulungile | I-ASTM G23 | |

Iingenelo zemveliso

1. Ulwakhiwo lweeseli ezivaliweyo

2. Ukuqhuba Ubushushu Obuphantsi

3. Ukuqhuba okuphantsi kobushushu, Ukunciphisa ngempumelelo ilahleko zobushushu

4. Ayitshisi, ayivali msindo, iyaguquguquka, iyanwebeka

5. Ukukhusela, ukulwa nokungqubana

6. Ufakelo olulula, olugudileyo, oluhle nolulula

7. Ikhuselekile kokusingqongileyo

8. Ukusetyenziswa: Umoya opholileyo, inkqubo yemibhobho, igumbi lestudiyo, iworkshop, isakhiwo, ulwakhiwo, inkqubo ye-HAVC.

9. Umsebenzi weMian: Ukutywina, ubushushu, ukulwa nenyikima, ubushushu besandi, ukuthintela umlilo, ubushushu, ukulwa ne-static, ukulwa nokwaluphala, ukulwa nokuguguleka, ukulwa noxinzelelo

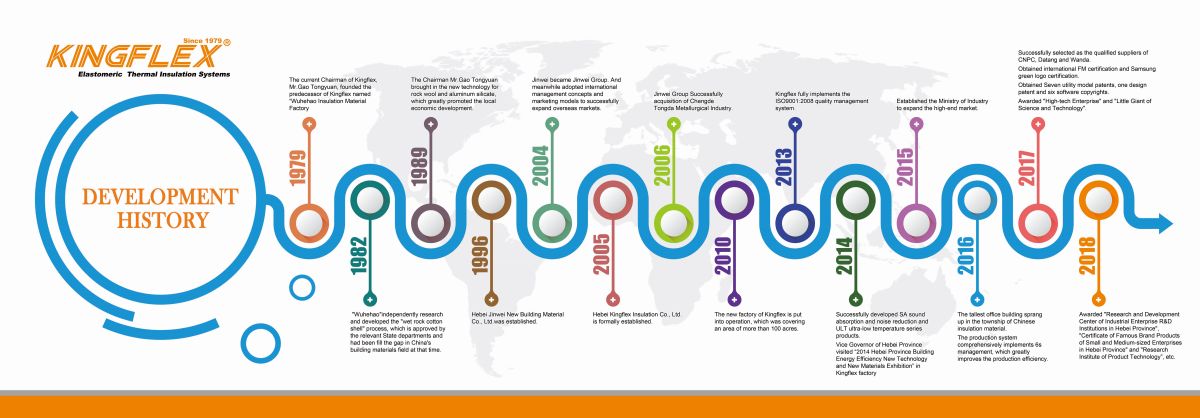

Inkampani yethu

Umboniso wenkampani

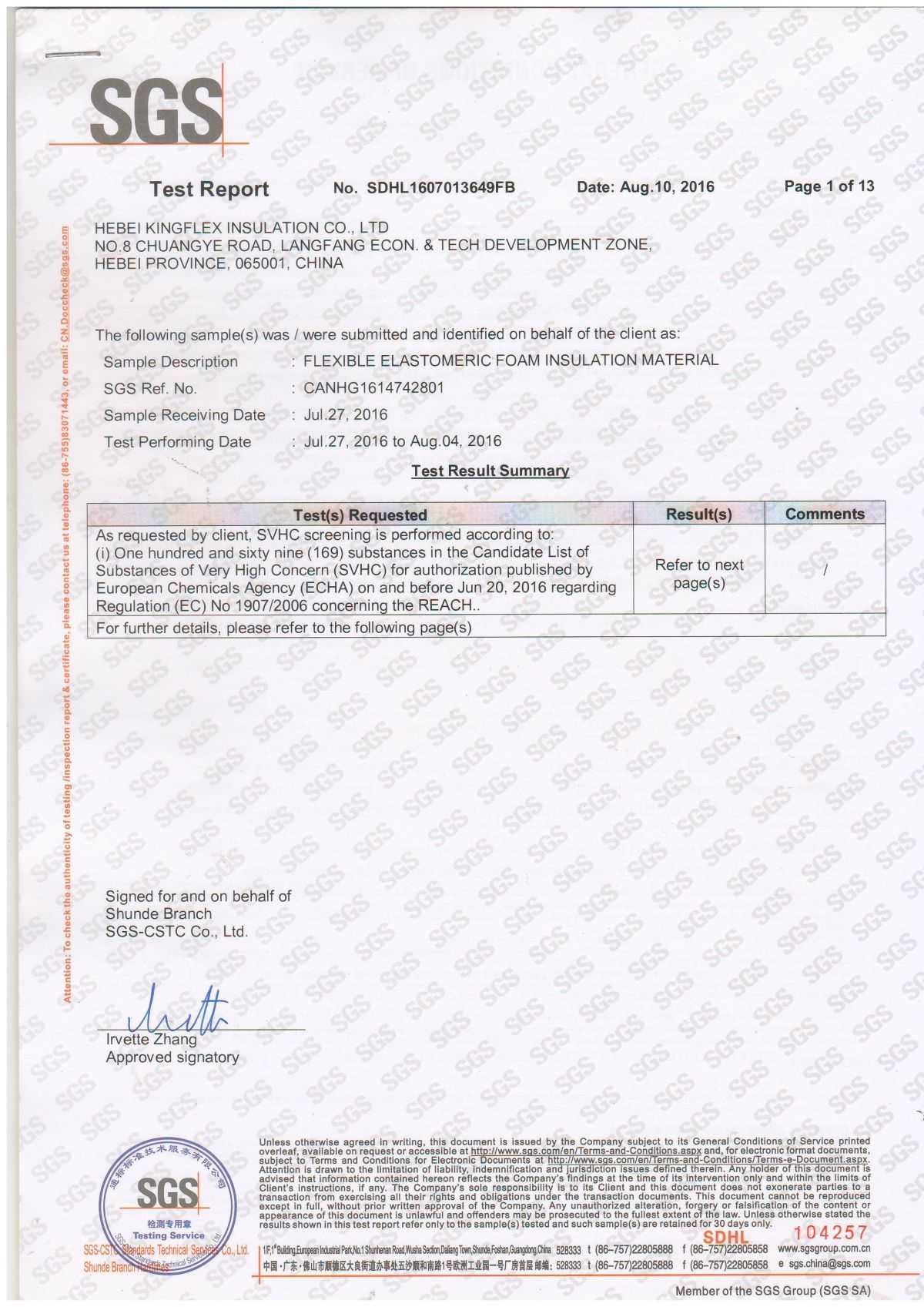

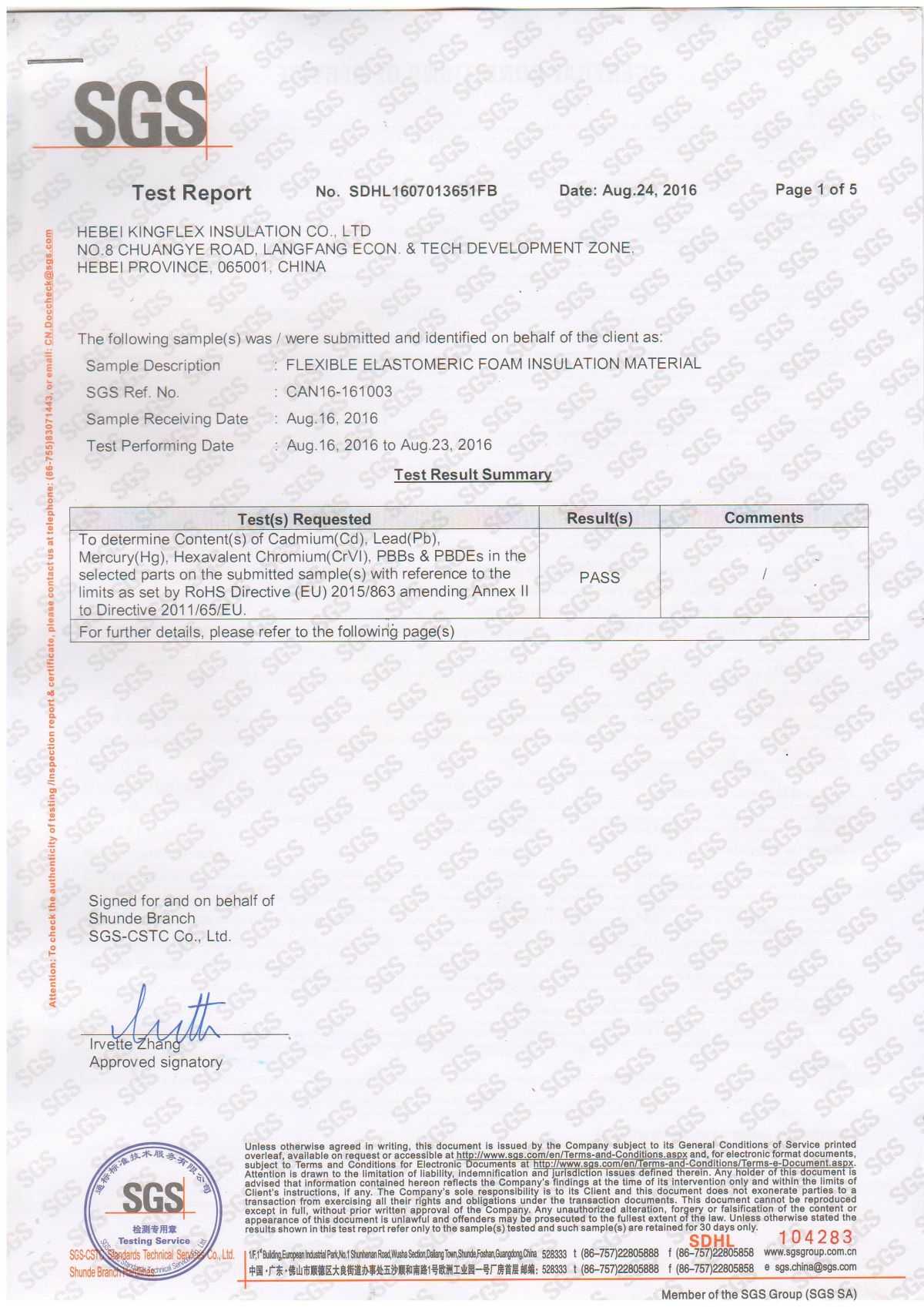

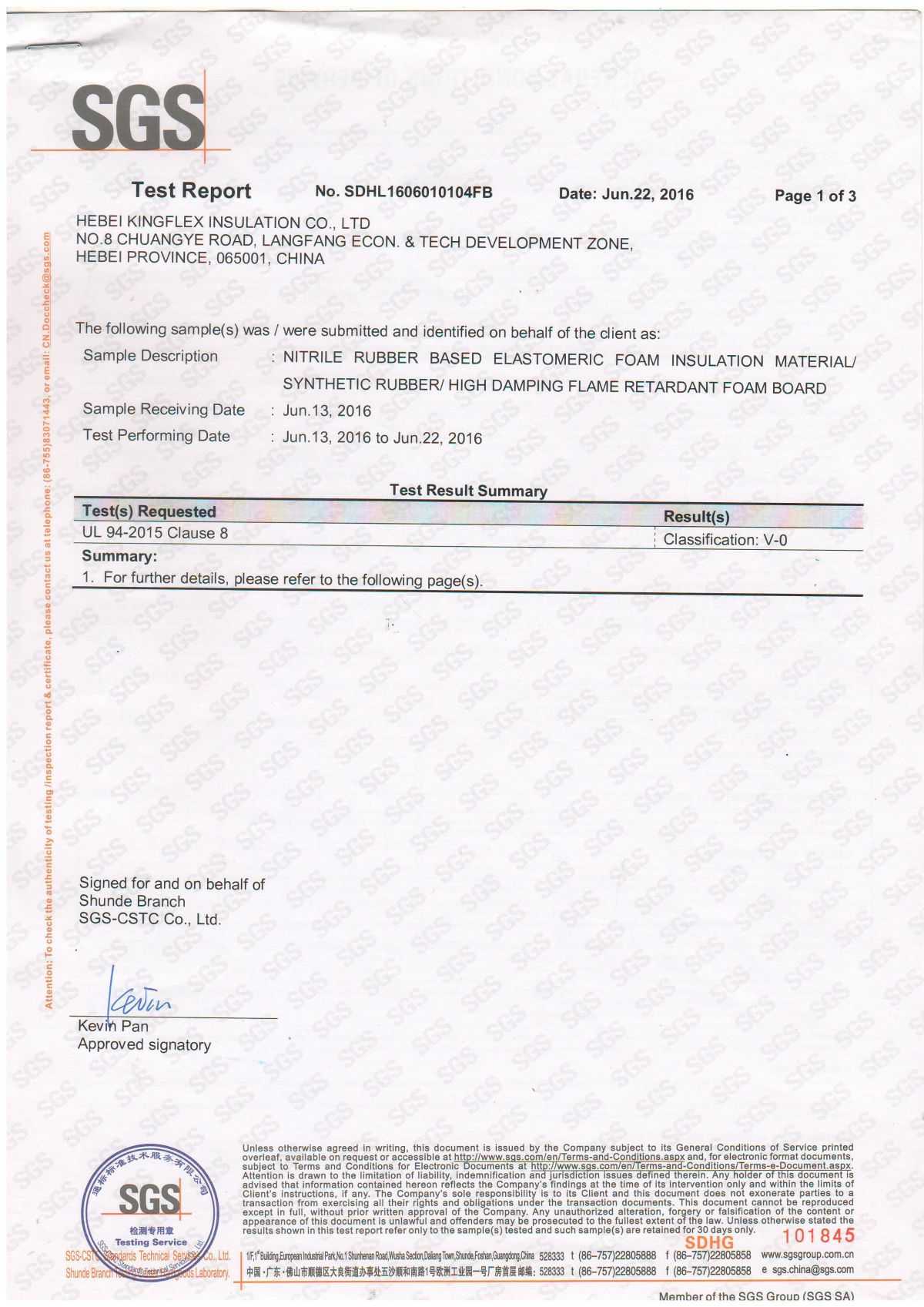

Isatifikethi

Iindidi zemveliso

-

Ifowuni

-

I-imeyile

-

I-Whatsapp